Quick background on myself, I live in the western foothills of Denver CO and moved here for the mountains. I ski inbounds and backcountry, ice climb, rock climb, mountaineer, backpack, mountain bike,.... about the only thing I stay out of is water. Boaters are nuts that water is cold!

Yes my basement looks like an outdoor gear store between all the climbing gear, ropes, tents, backpacks, stoves, and sleeping bags. So why add a camper? My wife and I have lived here in CO for 6 years now and we've hit a lot of what the front range has to offer and decided it's time to extend our range. We've come to learn Rocky Mountain National Park like our own back yard and want to start getting to more of the parks out west. Carrying our home on our back so we could get in more long weekends seemed like the next logical step.

So on to the build!

Here is what I brought home. A friend with a 96 F250 long bed was kind enough to lend me his truck for the transport. After a near death experience with a pair of rental cable camper jacks I got it safe and sound on some furniture dolly's and wheeled into the garage.

The interior was clean and well taken care of but I have an aversion to dark wood paneling so that’s going to have to go. Can't explain it. The interior doesn't have any smell to it but there's definitely a little mold on the side liner that I'll need to address:

On to the de-construction! Time to see what this FWC is made of and just how will I be spending my evenings after work.

First up the drivers side rear corner. I very quickly came to love my 1/4" hex driver in my cordless drill. The screws came out easy enough but the corners were held on with a combination of butyl tape and caulk. It comes apart easy enough but cleanup is a pain:

A little help from the persuasion bar

then a lot of screw removal and staple prying later voila!

a little siding removal and hmm this is going to take more cutting than I first thought

I want to keep the furnace so got to figure out what to do with that vent too

Of course no work can be done without a supervisor and I've got mine. She is always curious as to what I'm up to (just in the off chance what I'm doing involves dog food). This time she was happy to not have to take a spot on the concrete to watch

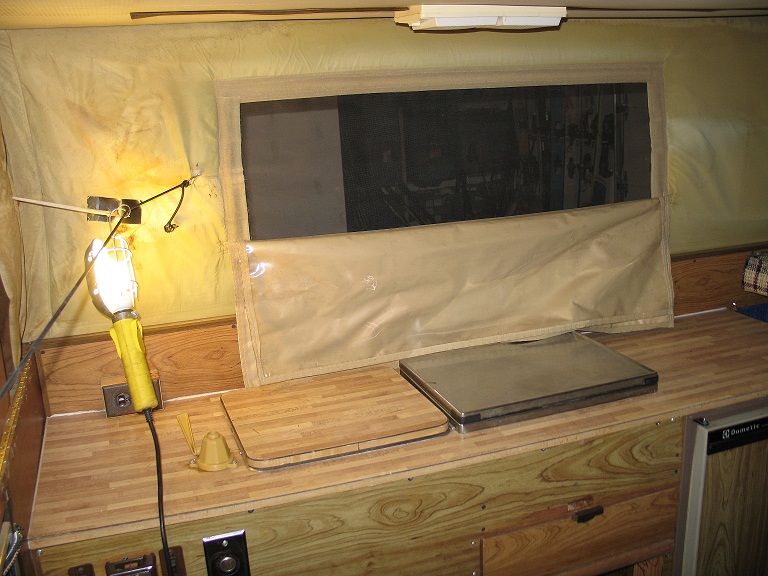

Since everything in the kitchen depended on what I was narrowing it all had to come out. Stove, sink, furnace, water tank, and fridge.

Hose clamps? We don't need no stinking hose clamps! How this was not surrounded by copious water damage will remain a mystery.