I wanted to post up on how I converted my 2018 Hawk (Tundra Build) to fit into my new Ram 3500, but I wasn't sure of the best name for this thread. The "un-tundra" build or something came to mind, but hopefully (if you're here) you have purchased a FWC Hawk from someone who had originally bought it for a Toyota Tundra, but now owns an Ford, Chevy, GMC, or Ram truck. -or- you can pass this along to someone who is in a similar situation as I found myself. I'm not 100% positive on the Titan XD, and some years of the F150 have a slightly taller bed. Be sure to measure, many times...

I've owned several Tundra's over the years; great pickups, and made right here in the USA by fellow Americans, albeit backed by a Japanese owned company on Japanese owned land in San Antonio, TX. (on a old cattle ranch dating back to 1794)

The time came for my wife and I to upgrade to my last pickup before I retire from my current career. so we just bought a leftover 2018 Ram 3500 Crew Cab Short Box, 6.7L Cummins, in Laramie trim level. This included pretty much everything but the adjustable pedals (factory 5th wheel & goose-neck hitch's also included). They were discounting them by about $11,000 since the 2020's where arriving on the lot, and they gave me $22,000 for my 2012 Tundra (and I only paid $29,000 for it in 2013).

One problem: When I installed the FWC eyebolts and loaded my Hawk it sat way up high in the Ram. The Tundra's have a 23" box and most others are just over 20" sidewall height. The almost 3 inch difference was just too much for me to take, and It looked rather strange and wasn't as aerodynamic as I'd have liked - so I decided to modify it.

After taking a look at things and calling FWC (who was very helpful by the way) I was informed that I could do it myself or bring it into them for a hefty fee.

I wanted to post up here how I did this in hopes that it would help others out who may be in the same situation. If need to clarify anything please post up or contact me and I'll get into more detail for you.

Here's the new Ram:

First step I did was to remove it from my roller-pallet and lift it up a bit:

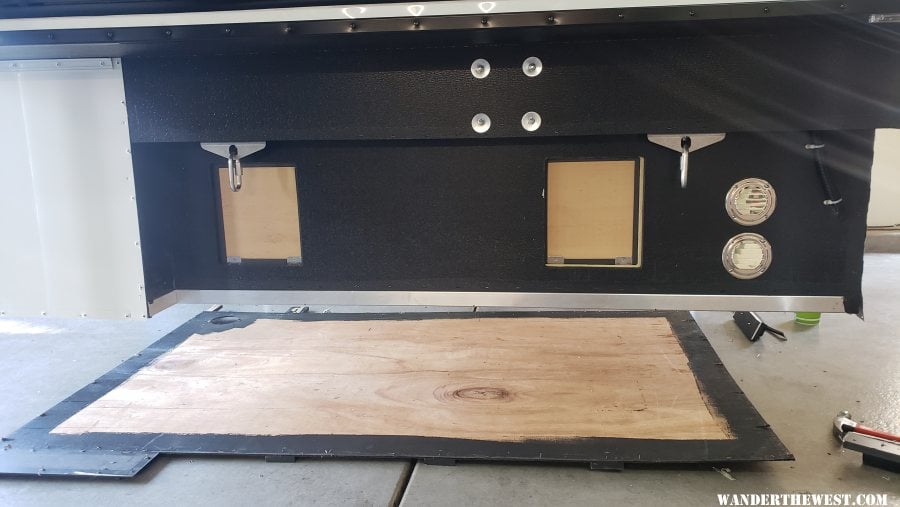

Another photo of removing the camper from my storage box, take note of the aluminum 'pallet' or 'floor pack' near the bottom of the camper that FWC installs onto their standard Hawk when ordering it to fit a Tundra (their Tundra build)

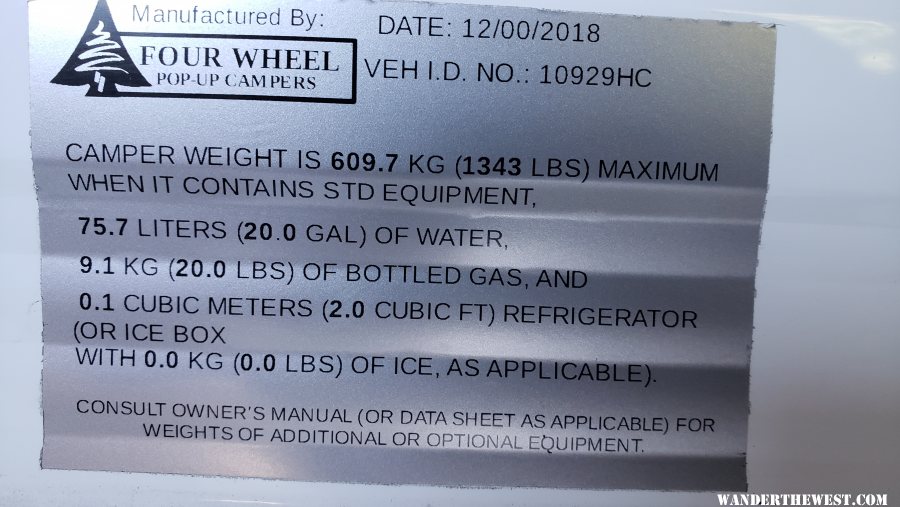

In this photo below, notice the factory VIN sticker near the bottom right. Later on in my thread you'll see that sticker almost disappear due to the shortening of the camper by nearly 3 inches. I'm literally removing that entire bottom below the rear door.

I'm showing this picture below because I used my camper storage box as a staging area to hold all the trim pieces - which had to be laid out so that they can go back onto the camper in the exact same spot so all the holes still line up.

Once the camper is in the air, you have to start removing the front bumpers first.

Removing the front bumpers, take note of how they are situated so you can get them in the same spot on the shortened camper.

Notice that I had originally cut my bumpers in half after ordering. This slides the camper forward right up almost against the front wall of your pickup. After measuring the new Ram this will prove to be an excellent option for this new truck as well, and it sits about 1/4" away from the front wall, just like the Tundra

Once the bumpers are unbolted, go ahead and remove all of the trim pieces and take note of where each piece was removed from so you ca re-install later. Notice that in the below picture I've already began pulling the little staples from the tin siding, and separating/pulling the siding from the frame.

I took photo's of how each piece of siding was mounted, so I knew where it went when I was done. Also, take note of the VIN sticker for later!

Trim laid out like it was removed:

Trim off, siding pulled away:

Use hammer and nail puller to pry the staples out of the wood for the bottom plywood:

Once you get all of the staples, the plywood will fall to the ground. FWC paints all the exposed wood with a flat black, outdoor acrylic paint (primer/paint combo). the main boards come as Gorilla Guard, but if you have bare wood, be sure to just paint them like FWC does so the don't rot over wet/dry cycles.

Part2 on next post:

Edited by River_Rat, 09 February 2024 - 09:06 PM.