Rear suspension mods needed for Hawk Shell on 3/4 ton truck?

#11

Posted 12 March 2022 - 05:11 PM

Tacoma/Fleet 2018.

#12

Posted 12 March 2022 - 06:49 PM

Stringer, et. al,

Rubberlegs, your suggestion is good. Knowing the weight of each axle is useful particularly if trying to decide on suspension changes.

Before I talked to Deaver Springs I took my truck - with camper on, full fuel tank, full water tank all my camping gear and Wendie in the passenger seat, to a local public scale and got weights for front axle, rear axle and the whole truck. I then measured the height of the front and rear fender wells off of the ground (on a flat surface). Finally I measured the distance from top of the axle to the bottom of the frame bumper stops for front and rear axle.

I provided that information to Deaver along with my description of the ride going over bumps and around corners. Jeff Crosby (the owner of Deaver Suspension) used all that info to build custom spring packs for both the front and rear. He suggested raising the truck 2" to get better axle to frame bumper stop clearance (to increase suspension travel). He also had me measure the original springs and provide that information as well - see the proper way to do that in a FAQ here: https://deaverspring.com/faqs/

I actually had Deaver ship the springs to the local Truck shop that usually works on my truck and the local shop installed them. The local shop also measured for new shocks because the new springs are 2" taller than the originals. Getting accurate shock compressed and extended lengths are important. We also had to talk about valving of the shocks. The valving controls how fast the shock rebounds. My mechanic (also does suspension) advised on the appropriate valving selection. The Bilstein shock model I chose had two standard valving configurations for the lengths I needed. Custom valving is of course available but I was not prepared to get into that.

It turned out that the rear spring height after install was too low. I had to drive it that way for awhile and the sway was bad. The truck rolled too much when cornering. I contacted Deaver and explained the issue with rolling. Jeff said he apparently made a mistake designing the rear spring pack and recommended just bringing the truck there to let them make it right. I made an appointment to bring the truck down and they removed, rebuilt and reinstalled the rear spring pack in an afternoon (no charge of course). Jeff said that if I have any additional issues just call make an appointment and bring it back in and they will make it right. He said that the softer springs will still give a bit more roll on cornering than the original stiff springs and suggested adding a rear sway bar if it is more than I am comfortable with.

After driving the truck a few hundred miles on combination of freeway and around town I decided to order a Hellweg sway bar for the rear. I am also going to order a 2" drop Pittman arm as the angles on the original Pittman arm are a bit more than optimal.

I am happy with the new Deaver springs and I recommend Deaver.

All that written, I was a suspension novice going into this. I have learned a lot. I strongly recommend going to a suspension shop that is familiar with 4x4 light trucks, particularly on whatever make and model you have, and discuss options before jumping into any suspension modifications. As with most modifications there can be unforeseen consequences to a change which may lead to a succession of changes.

Side note: The Deaver shop is a step back in time. It is in a former blacksmithing shop. The overhead belt pulleys and shafts for equipment are still in place and there is one belt drive drill press still in use. The company was founded in 1892 by blacksmith Frank Deaver and made Buggy Springs and transitioned into motor vehicle springs. They have been in that building since the 1920's when they moved from the first shop that was across the street (now an apartment complex) and the company has been owned by 4 successive generations of the same family.

I hope some of this info is useful.

Craig

Edited by ckent323, 12 March 2022 - 08:32 PM.

1993 Dodge Cummins W-250 Club Cab long bed, 2007 FWC Keystone

#13

Posted 12 March 2022 - 09:20 PM

Some truck stops have private scales and I've found those to be more agreeable in dealing with non OTR trucks.

A footnote, Craig, that 2" drop pitman arm is going to work the lower bushing in the steering box a bit harder. If they are offered for your truck I'd look into the bolt-on support bearing kits that place a bearing below the pitman arm by using a custom nut.

Where does that road go?

#14

Posted 12 March 2022 - 11:24 PM

ntsqd,

Thanks I'll look into that.

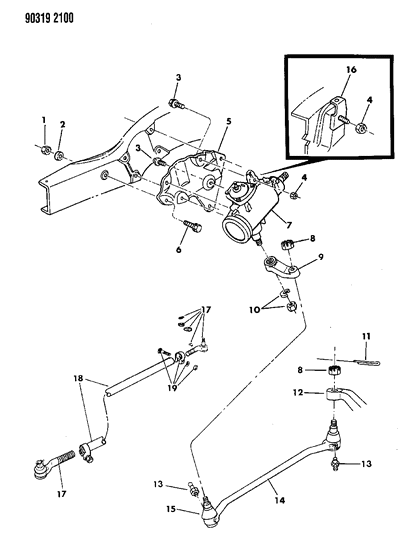

However, I'm not sure I understand the issue. Presently the hole in the Pittman arm (9) is not orthogonal to the bushing bolt (13,15) on the drag link (14). Although, the bushing itself is cone shaped so that centers it up. It seems to me this puts an uneven load on the drag link bushing at the Pittman arm and also at the drag link steering arm bolt and bushing (12) (note: my drag link is solid not adjustable).

Since the cone shaped bushings are compliant doesn't that minimize any load on the steering box (7) spline, whose relationship is held orthogonal because of the shaft and spline? It seems to me this is a wear issue on the drag link bushings and may effect the steering a little because of the angles of the bushing bolt to the Pittman arm. I am no expert on this so I'm not sure I understand the interactions of all these parts and what happens when things are changed.

In my research on lifting these trucks (1993 Dodge Ram W250) I read that when these trucks are raised 4" or 6" a dropped Pittman arm is required (for example, Skyjacker makes 2", 4" and 6" drop Pittman arms for this truck model to go with their various lift kits). That written I did not see any requirement to replace the stock Pittman arm for a 2" lift only that it was suggested.

Writing this up which is making me think more about this, I realize one thing I have not done (and will do) is to check to see if the drag link is still parallel to the ground or if it is at an angle to the ground. If it is still parallel with the stock Pittman arm then a drop Pittman arm is probably not the right thing to do (that would probably make it not parallel to the ground).

The following diagram shows my steering linkage.

Edited by ckent323, 12 March 2022 - 11:42 PM.

1993 Dodge Cummins W-250 Club Cab long bed, 2007 FWC Keystone

#15

Posted 12 March 2022 - 11:50 PM

OH! I assumed that those trucks were like their 2wd cousins and the second+ gen CTD's with a drag link that crosses the chassis CL. There may not be such a kit made given the drag link being parallel to the chassis CL. The issue is that even though you haven't increased the center to center length of the lever, it is now working in a plane that is 2" lower than the lower sector shaft bushing was designed for. If that seal at the bottom of the box starts to leak it more than likely is because the bushing is starting to wear. You may or may not notice the subtle lack of steering I/O loss.

Anyway, OP, I think that you'll find the existing springs are more than up to the task. I'm assuming that your Silverado is fairly late model in which case the rear springs under it are THE spring to use in a LOT of rock crawlers (after removing a leaf or three). They're a very good design that rides well.

Once the Chucara XL had been in our truck for a while I noticed that the rear springs were sagging. Worse they were sagging at an angle due to the poor location of the pair of 2GC batteries (as far the right rear is is possible). Not long ago I had our local 4WD Specialist replace those springs with new, OEM type springs. He wanted them ordered for the max load capacity offered, so in effect he put 1 ton rear springs under the truck, and then tuned them (by selectively removing leaves) to sit level with the camper in the truck. My point being that if they do sag that you likely have an OEM spring type option as well. Delivered these OEM type replacement pair of springs cost about what one Deaver spring costs. Not to say that Deaver's are not worth their price because they are. (I have a set of Deaver's under the FSB that I wouldn't trade for any stock spring.) Just that there may be lower cost, reasonable quality options. I believe that the springs that I bought for our camper came from General Spring.

Where does that road go?

Also tagged with one or more of these keywords: Hawk, shell, suspension

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users