Anyway.. The gallery is here: http://www.wanderthe...nkyard-project/

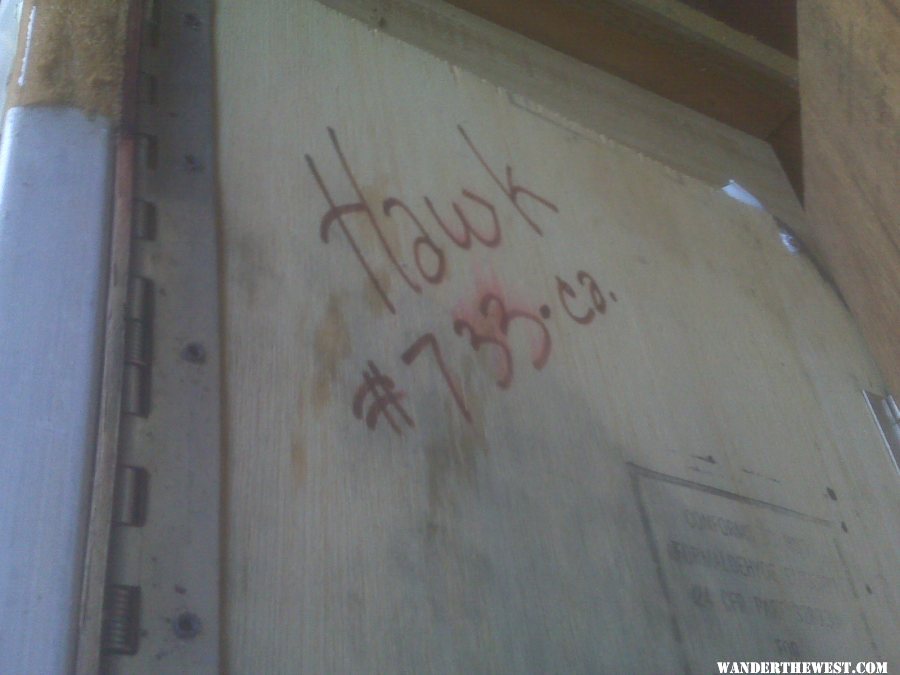

How it looked in the yard

It had a modified front cab. Actually pretty clean but my goal is to lighten it up as much as possible for my Dodge Dakota..

So the first thing was to remove the cap..

Actually by that picture most of the interior had been gutted, including the pop up material which was shot (any suggestions for places in Sacramento to get a replacement?)

The one side of the upper bed was bent down so this is part of the reason for the tear down. It was also pretty waterlogged so removal of the plywood was in order

A beforeish inside picture

The pile of some of what has been removed (much more to come!)

Hard to see but this is the bent side, the oak reinforcement wood is broken and the welds on the frame are broken. Really surprised how little they are welded, you'd think you'd weld it more but I guess that is production for you

The other side as it sits

I don't have much time in yet. Not real sure where this is going but the current plan is to get it down to the aluminum frame. Then I am pretty sure I will weld up a lot of the frame that is just tacked now to make it a bit more rigid since I won't be putting back nearly as much of the inner support structure (weight weenie). I would like to see if I can get a new upper channel (Stan?) to put in since mine is in pretty bad shape. Once I get it down to that point I will build it back up maximizing the space to the contour of my bed. Not sure if I will use plywood for the bottom like what is in there now or not. I'd actually like to build it with no wood but we'll see if I go through with that. Anyway, picked it up just last weekend so this has just begun. I am not known for quick projects but I have built quite a few vehicles, houses, etc. Licensed Civil engineer by trade, fabricator by hobby.